Performance, Adaptability and Strong ROI

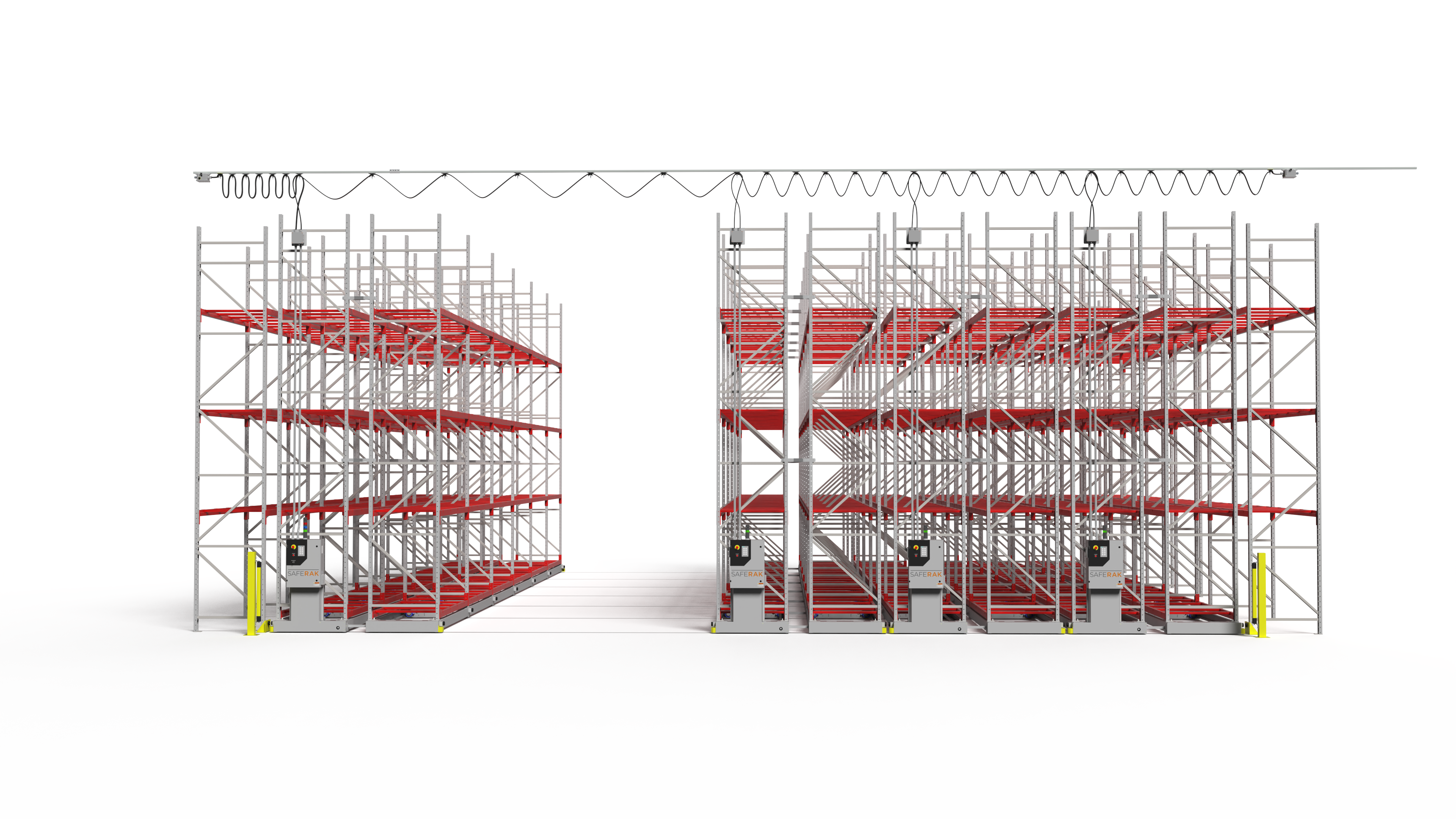

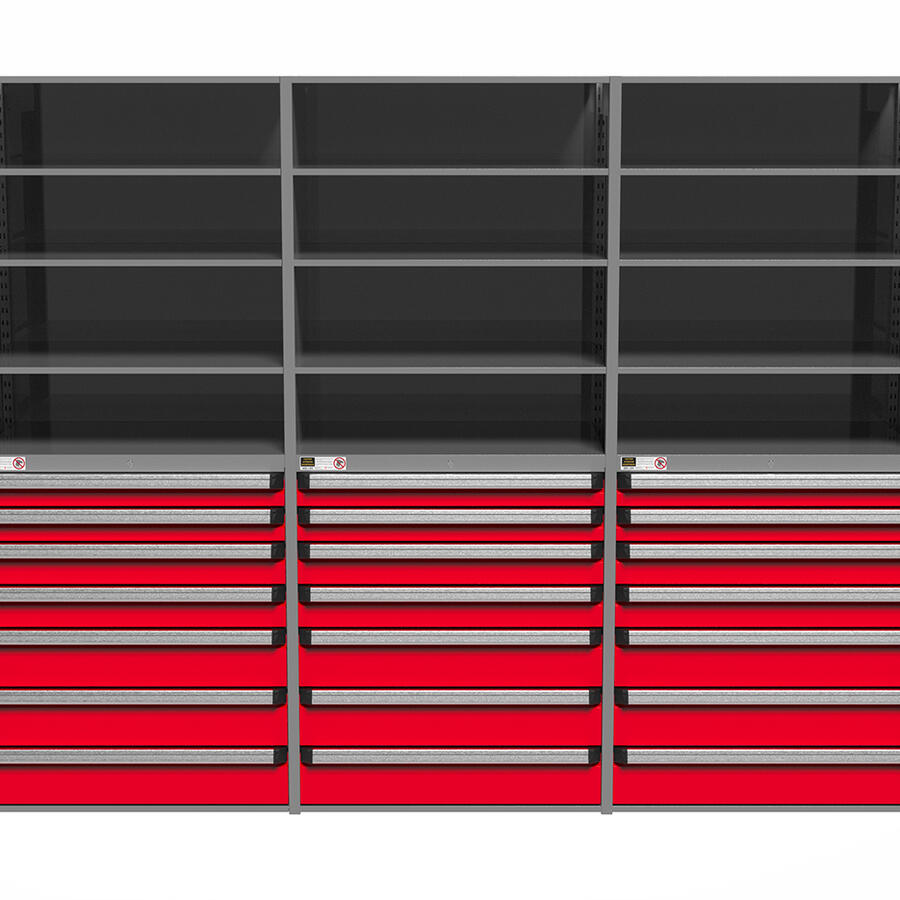

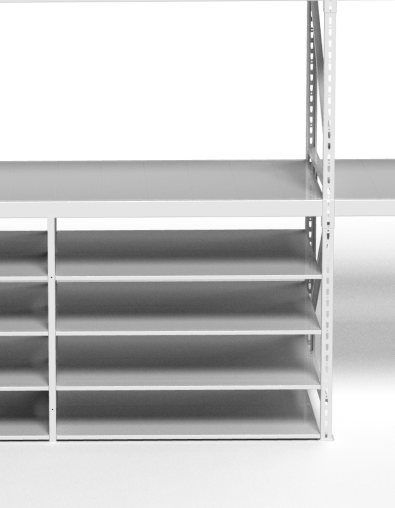

Response time is at the heart of the operations at your distribution centers. Our storage solutions, which are adapted to your market, will enable you to improve productivity, shorten delays and increase performance.

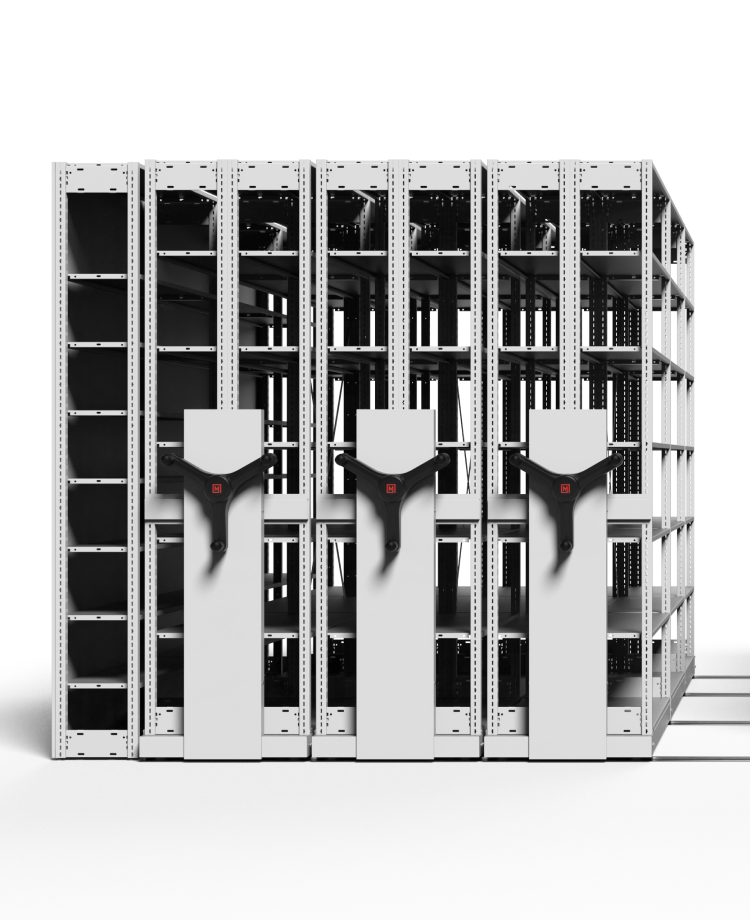

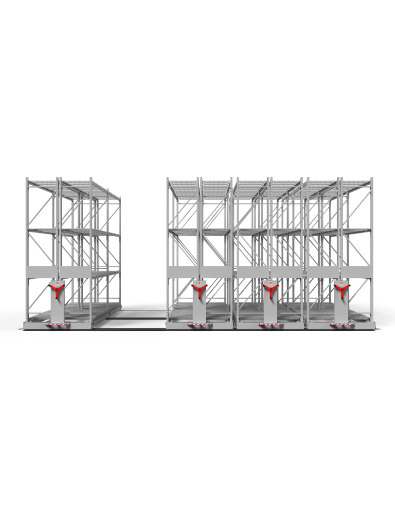

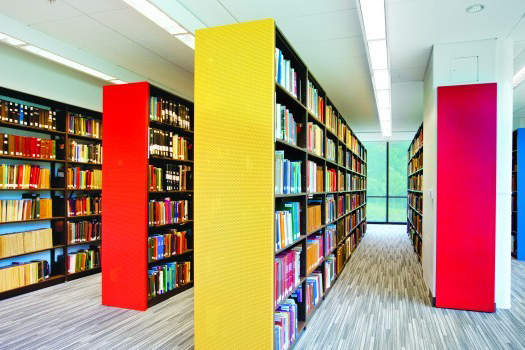

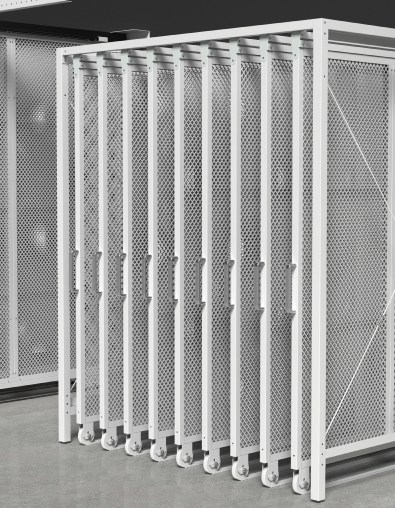

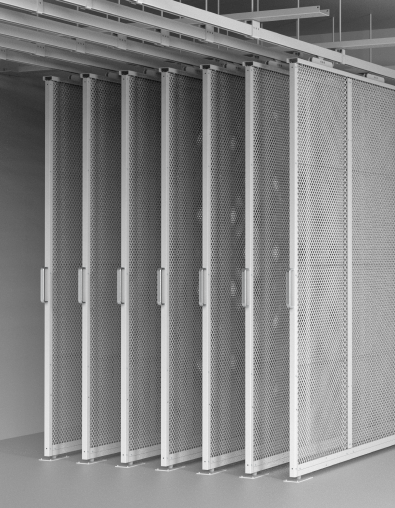

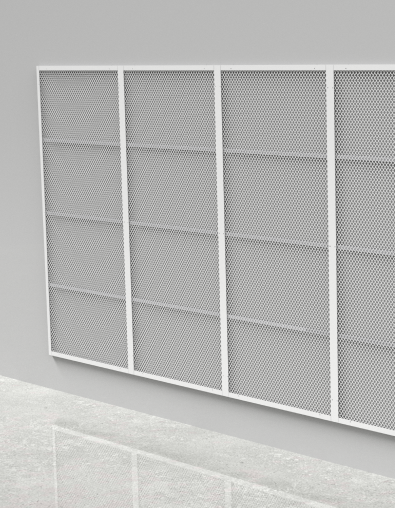

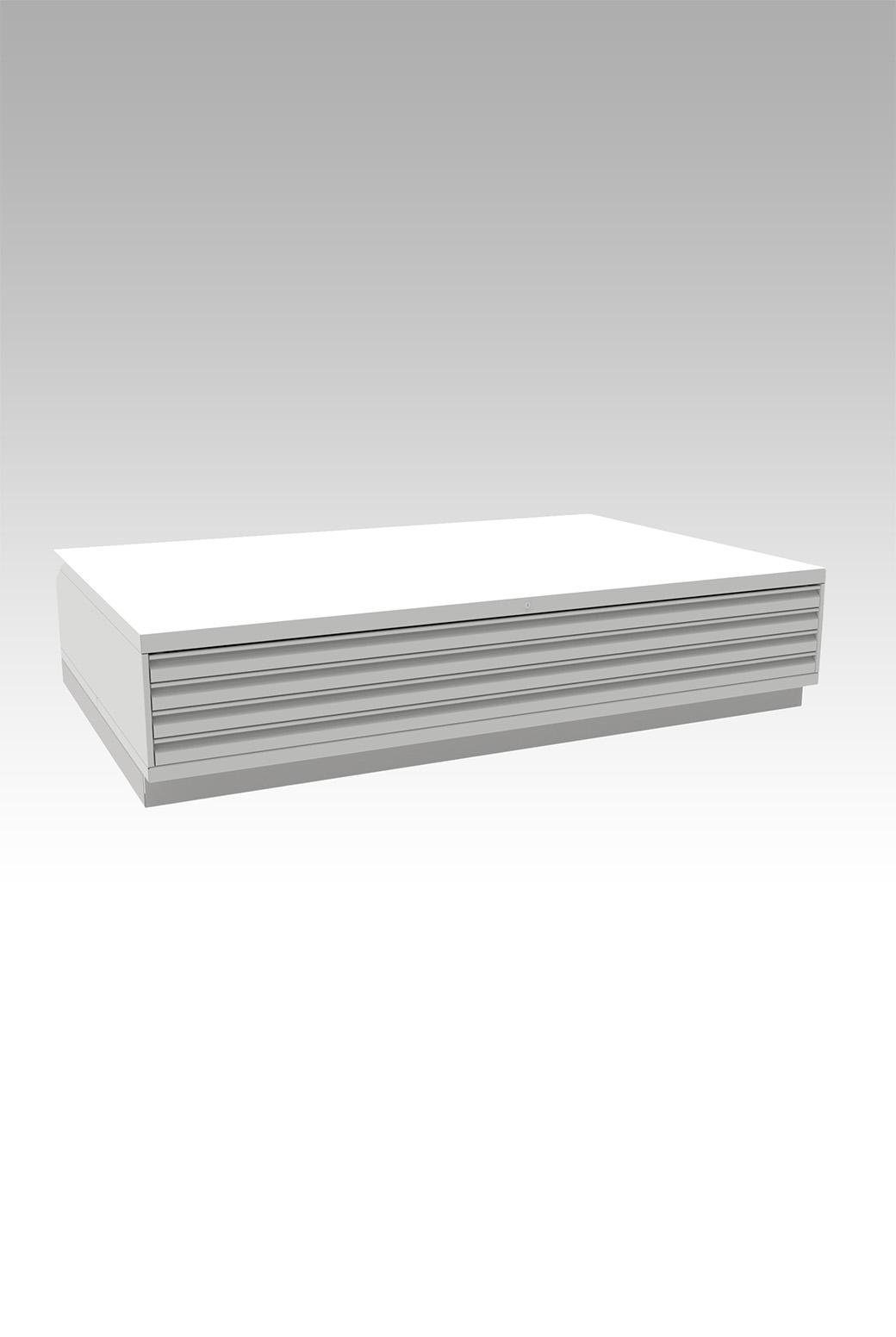

See how our compact, modular, flexible and scalable mobile or static solutions can accommodate your activity. If you're interested in high-density mobile shelving systems that can save you time and money, ask about our compact and modular mobile solutions.

With them, you can increase your storage density by 50%. Our high-density mobile racking and shelving systems are an incredibly efficient option for slow-moving, heavy or bulky items, cold storage, time-sensitive items, and pretty much any situation that necessitates better use of valuable floor space in your distribution center. Contact us so we can help you solve your storage issues.