High-Density Vertical Grow Systems: The Infrastructure Powering Modern Indoor Horticulture

Insights on vertical farming - February 19th 2026

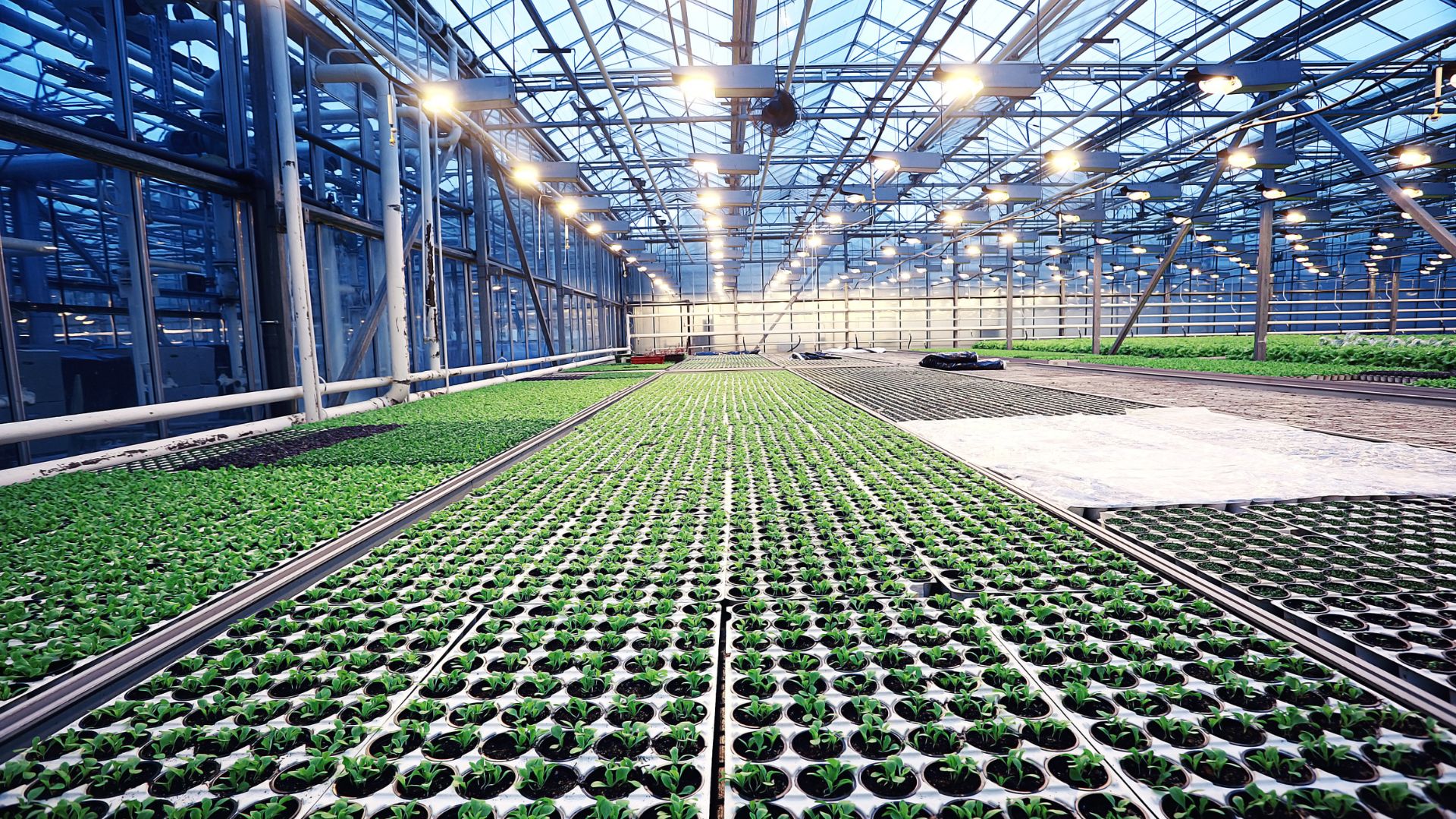

As indoor growing environments scale, vertical density becomes a defining performance variable. The way crops are organized, accessed, supported, and serviced shapes climate stability, workflow efficiency, and biosecurity. In this context, high-density grow systems are not merely structural components — they are the infrastructure that enables modern indoor horticulture to perform.

Today’s advanced vertical growing systems function as integrated platforms. They align cultivation support, environmental management, circulation, and access into a unified operational framework — allowing facilities to operate with precision, predictability, and control.

For farm operators in the USA, Canada, and Europe, adopting high-density grow systems as core infrastructure is key to achieving profitability and operational scale.

High-Density Mobile Grow Systems as an Operating Model

A primary driver of yield and scalability in indoor horticulture is the transition from static shelving to high-density mobile vertical growing systems. These systems consist of grow racks mounted on mobile carriages that travel along floor tracks, eliminating fixed aisle space and allowing access through a single moving aisle.

Where static configurations require an aisle between every two rows, mobile systems consolidate access into one shared corridor. Racks move laterally on rails to create an aisle only where needed, reducing permanently allocated access space. This design maximizes active growing area — often doubling or tripling canopy density within the same building footprint.

Equally important, these systems fully leverage the vertical volume of a facility, frequently exceeding 26 feet in height. In space-constrained urban environments such as New York or Amsterdam, this level of vertical utilization is not optional — it is foundational to viable indoor horticulture.

Beyond maximizing space, high-density mobile systems also reduce energy consumption. By consolidating access into a single movable aisle, lighting is activated only where work is taking place — never over empty space. Minimizing permanently lit corridors lowers overall lighting demand and reduces HVAC load, since fewer non-productive areas require cooling or airflow. The result is greater canopy density with lower operational energy costs.

Access, Movement, and Safety by Design

High-density mobile growing systems are engineered to remain practical at scale. Mechanical-assist handles or electric drives allow fully loaded racks to move smoothly and with minimal effort, even at significant height and weight.

Safety is built directly into the operating model. Modern systems incorporate integrated crosswalks, anti-tip mechanisms, and structural safety locks to ensure secure access across all levels. This protects both personnel and high-value crops while enabling consistent, repeatable workflows.

Integrated Growing Infrastructure

High-density vertical growing systems are no longer standalone structures. They function as the backbone of the cultivation environment itself. They support integrated lighting, irrigation, airflow, and environmental controls — ensuring that every layer of production operates within a coordinated system rather than isolated components.

Understanding High-Density Vertical Growing Systems — Q&A

Q: What is the primary benefit of high-density mobile vertical growing systems?

A: Their primary benefit is maximizing active growing canopy by eliminating fixed aisle space. This allows operators to significantly increase production capacity—often doubling or tripling usable growing area—within the same building footprint.

Q: How do mobile vertical growing systems support worker safety?

A: These systems are engineered with integrated safety features such as mechanical-assist or electric drives, anti-tip mechanisms, structural safety locks, and built-in crosswalks. Together, they ensure secure access to all growing levels while supporting efficient daily operations.

Q: What does “integrated racking” mean in indoor horticulture?

A: Integrated racking refers to growing structures designed to incorporate lighting, irrigation, airflow, and utilities directly into the system architecture. Rather than acting as standalone frames, these systems function as the structural backbone of the cultivation environment.

Q: Where are containerized vertical growing systems typically deployed?

A: Containerized systems are commonly used in space-constrained or non-traditional locations, including dense urban areas, rooftops, and remote communities. Their modular design allows for rapid deployment and consistent performance across sites.

Q: How do smart technologies improve the efficiency of vertical growing systems?

A: Sensor networks and data-driven controls monitor environmental conditions such as temperature, humidity, and CO₂ at each growing level. This enables precise adjustments to lighting, airflow, and nutrient delivery, improving yield consistency while reducing resource waste.

Q: What role do mobile carts play in indoor horticulture workflows?

A: Purpose-built mobile carts support movement between cultivation stages—such as cloning, growth, or drying—without disrupting high-density growing configurations. They help maintain clean workflows and operational continuity across the facility.